From concept to creation—your one-stop 3D design partner !

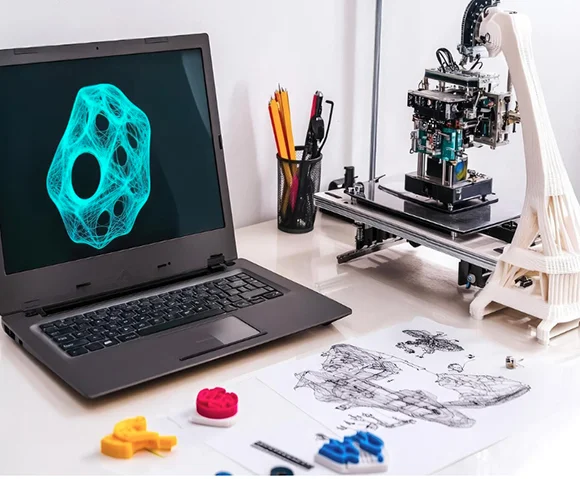

Custom 3D Model Design

At Melt Engineering, we specialize in creating high-precision 3D models tailored to your specific project requirements. Whether it's for product prototypes, industrial components, or complex tools, we ensure every design is optimized for functionality and manufacturability. Our team collaborates closely with clients to understand their vision and deliver detailed models that align with their industry needs. By leveraging the latest 3D design software and techniques, we bring your ideas to life with accuracy and speed. Each model is meticulously crafted to meet stringent quality standards and ensure seamless integration into your production process.

Design Consultation

Navigating the world of 3D design can be complex, and that’s where our expertise comes in. Our design consultation services help you refine your product ideas for optimal performance, manufacturability, and cost-efficiency. We evaluate your concepts, suggest design improvements, and ensure compatibility with 3D printing technologies. Whether you're working on a prototype or a production-ready part, we guide you every step of the way. Our goal is to help you make informed design decisions that save time and resources while enhancing the final product. Together, we transform ideas into tangible, functional solutions that drive innovation.

Rapid Prototyping

Speed matters when you're testing ideas, and our rapid prototyping service delivers functional prototypes in record time. We help you iterate quickly, enabling you to test form, fit, and function before moving to full-scale production. Our prototypes closely replicate final products, providing valuable insights into design improvements and manufacturing feasibility. With rapid turnaround times and precise detailing, we support your development cycle at every stage. From initial concepts to fine-tuned models, our prototyping services empower you to innovate with confidence.

Reverse Engineering

When parts are no longer available or documentation is incomplete, our reverse engineering services help you rebuild with confidence. We use advanced scanning and modeling techniques to capture precise dimensions and recreate detailed 3D models. Whether you need to restore obsolete components, improve existing designs, or adapt legacy parts for modern use, we provide accurate, production-ready models. Our expertise ensures seamless integration into your manufacturing processes, minimizing downtime and maximizing efficiency. We transform outdated components into new opportunities for innovation.

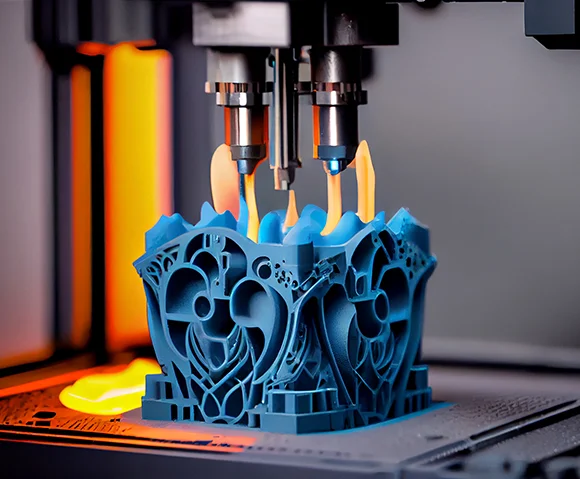

Design for Additive Manufacturing (DFAM)

Additive manufacturing requires a unique design approach, and our DFAM service helps you make the most of it. We optimize your models for 3D printing, ensuring they are structurally sound, lightweight, and material-efficient. Our team works with you to redesign parts that leverage the strengths of additive technology, such as complex geometries and internal features. This results in components that are not only functional but also cost-effective to produce. By aligning your designs with AM best practices, we help you unlock new levels of performance and innovation.

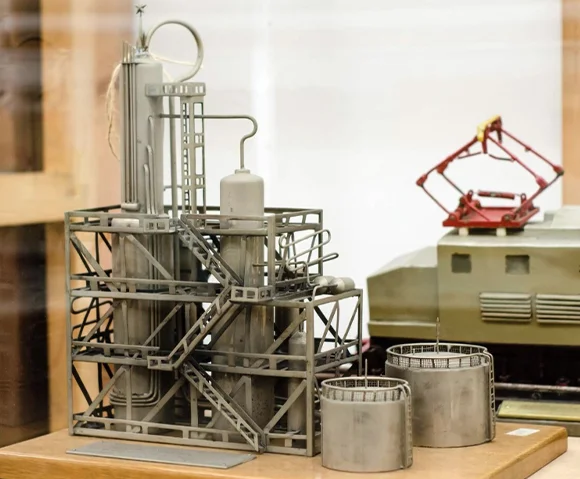

Miniature Model

Showcasing large-scale industrial machines or process plants in a compact, detailed format can be challenging—but that’s exactly what our miniature models achieve. We create high-precision scaled models that demonstrate complex processes and machinery in an engaging and accessible way. These models are ideal for exhibitions, marketing presentations, and educational purposes, offering a tangible representation of your systems. Each miniature is carefully crafted to capture every essential detail, from intricate components to overall layout. Our expertise ensures that your miniatures are accurate, visually striking, and tailored to your specific industry needs.

Low-Volume Production

For projects that require high-quality prototypes or limited-run parts, our low-volume production service is the perfect solution. We produce parts that closely resemble final products, making them ideal for pilot testing, market validation, and small-batch applications. Our expertise ensures that each part meets stringent quality standards and is ready for practical use. By bridging the gap between prototyping and mass production, we help you move from idea to market faster. Whether you need a few units or a small series, our low-volume production offers flexibility, precision, and value.